How Many More? The Alarming Rise of Fires in Texas and Louisiana Oil Plants

Alarming Trends in Oil & Gas Safety Failures: Fires and Explosions Surge Across the Gulf Coast

In May 2023, a catastrophic fire and explosion in an olefin unit at a Shell USA refinery in Deer Park, Texas, sent nine workers to the hospital. This same facility had reported four malfunctions since the beginning of 2022, each resulting in unauthorized pollution releases, but it received no fines or citations. Instead of a fine or requiring a fix for the dangerous malfunctions, Texas’ “Affirmative Defense” law allows oil and gas companies to put off required maintenance or upgrades. That’s little comfort to the workers who suffered life-altering injuries or to the communities plagued by pollution from the plant.

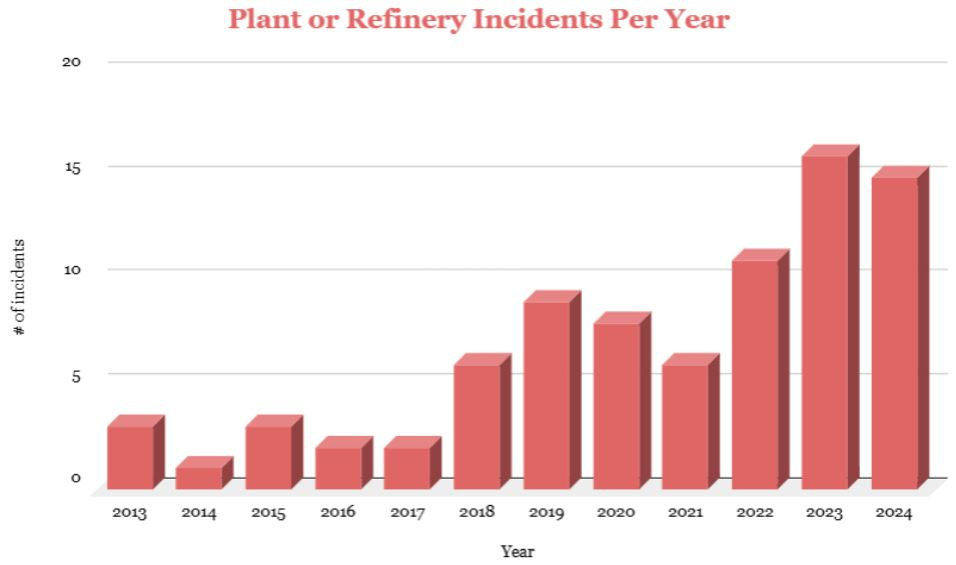

The Shell Deer Park incident is just one of dozens of recent examples. Over the last decade, the oil and gas industry in Texas and Louisiana has witnessed an alarming rise in fires and explosions at petrochemical plants, exposing severe safety failures and regulatory gaps. Between 2019 and 2024, incidents at these facilities was nearly quadruple the number of incidents in the preceding six years, signaling a troubling trend for workers, communities, and the environment.

A Crisis in Safety

Data compiled from the U.S. Chemical Safety Board, OSHA reports, local news, and watchdog groups paints a distressing picture of the rising frequency of fires and explosions at oil and gas plants across the Gulf Coast. From 2013 to 2024, 82 significant fires and explosions were documented at oil, gas, and petrochemical plants in Texas and Louisiana. When you look at the data, what particularly stands out is the concentration of these incidents in recent years: a staggering 79.3% occurred between 2019 and 2024.

This trend shows no signs of abating. Through all of 2024, 15 additional incidents were reported, leaving the Gulf Coast oil & gas plants and refineries nearly matching the catastrophic totals of the prior year. Despite decades of promises to improve safety protocols, the industry’s performance is, by every measure, getting worse.

Regulatory Failures: Promises vs. Reality

After Hurricane Katrina in 2005, which underscored the Gulf Coast’s vulnerability to industrial disasters, new regulations were introduced to modernize safety practices. Facilities were tasked with upgrading equipment, enhancing emergency response plans, and meeting stricter environmental guidelines. Yet, decades later, many of these measures have fallen short.

Robert Bea, a retired engineering risk professor from the University of California, Berkeley, noted that each hurricane has exposed a troubling pattern: both industry and regulators tend to react to storms rather than prepare for them. "It's called waiting for the next failure," Bea said. "It's being reactive, not proactive."

Regulatory agencies like the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) are frequently understaffed and underfunded, limiting their ability to conduct thorough inspections and enforce penalties. Furthermore, the small fines imposed for safety violations are rarely seen as serious deterrents; instead, they are often treated by the industry as just another cost of doing business.

The Human Cost: Workers and Communities Left in Harm’s Way

The rising number of fires and explosions poses a direct threat to workers and nearby communities. Oil and gas plants are often located in low-income areas, where residents already face systemic barriers to healthcare and environmental justice. Fires release toxic chemicals into the air, leading to respiratory illnesses, cancer clusters, and long-term health crises for those living downwind.

Workers, meanwhile, are on the front lines of these disasters. They are the first to experience the physical dangers—burns, smoke inhalation, and in some cases, death. Yet, their stories are often overlooked in the broader narrative. The lack of comprehensive injury and fatality data makes it difficult to quantify the true cost of these safety failures.

In one recent incident, a massive chemical leak at a PEMEX refinery in Deer Park, Texas, left two workers dead and 35 injured and placed the nearby community under a cloud of toxic gas while failing to issue a warning about the release.

"These communication failures left the community wondering whether they were safe, and that is absolutely unacceptable," said Harris County Precinct 2 Commissioner Adrian Garcia.

“We shouldn’t tolerate it anymore,” said Luke Metzger, the executive director of Environment Texas. “We need the state, the federal government to come in and force these companies to follow the law. Stop this pollution. Stop these deadly incidents.”

Industry Profits vs. Safety Investments

Despite record-breaking profits in recent years, oil and gas companies appear reluctant to prioritize safety upgrades. According to financial disclosures, many leading companies in the region have allocated tens of billions to shareholder dividends and stock buybacks but far less to modernizing infrastructure or improving safety measures.

“The average age of a US refinery is over 40 years, with some dating to the end of the 19th century, and they mostly have inadequate pollution control systems,” writes Cecilia Moura at the Union of Concerned Scientists.

Aging facilities are a major contributing factor to the rise in incidents. Many Gulf Coast refineries and plants were built decades ago and now operate with outdated equipment prone to failures. Regular maintenance is costly, and when faced with profit pressures, companies often delay upgrades until disaster strikes.

Accountability: A Systemic Failure

When fires and explosions occur, accountability is often limited. Fines levied against corporations are typically minimal compared to the profits these companies generate, leading critics to argue that penalties are seen as little more than a cost of doing business.

In cases where lawsuits are filed, families of injured or deceased workers face long legal battles with powerful corporate legal teams. Settlements, while sometimes significant, rarely address the root causes of these disasters, allowing the cycle of negligence to continue.

Furthermore, the Gulf Coast’s economic reliance on the oil and gas industry complicates efforts to hold companies accountable. These corporations are major employers and contributors to state economies, making local officials hesitant to take action that might disrupt their operations.

A Call for Change

The rising frequency of fires and explosions in the oil and gas industry is more than just a series of unfortunate accidents—it is a systemic failure that demands urgent attention. Workers and communities cannot continue to pay the price for corporate neglect and regulatory inertia.

Experts argue that immediate steps are needed, including:

Stricter Enforcement of Safety Regulations: Agencies like OSHA and the EPA must be empowered with greater funding and authority to conduct inspections and enforce meaningful penalties.

Mandatory Safety Upgrades: Oil and gas companies must be required to modernize aging infrastructure to prevent equipment failures.

Transparency and Reporting: State and federal agencies should establish a public, centralized database of incidents to ensure accountability and oversight.

Community Protections: Residents living near oil and gas facilities need access to comprehensive health monitoring and emergency response systems.

Conclusion

The surge in fires and explosions across the Gulf Coast’s oil and gas industry is a stark reminder of the human and environmental costs of systemic neglect. While companies continue to reap profits, workers and communities face escalating dangers that show no sign of abating.

The data is clear: without immediate reforms, these incidents will only become more frequent and more devastating. The question remains—how many more disasters will it take before safety becomes a priority?

For workers like those in Texas and Louisiana, and for families living in the shadow of petrochemical plants, the stakes couldn’t be higher.

Note: This article was updated to reflect the completed 2024 report. (1/31/2025)